Electronics are increasingly present in our lives, these

technologies all use a wide array of components -sensors,

actuators,central processing units (CPUs), printed circuit boards

(PCB), electronics componnets , Capacitor, power supply,

transformer,ignition coil, reverse sensor, circuit board, filter

products ,underwater parts, electronic ballast ,aviation parts,

aerospace parts....etc. - that need to be protected against

environmental factors such as dust and moisture, as well as fluids

and heat and

fire exposure.

Advanced Solutions in Dispensing and Potting Equipment

In today's rapidly evolving manufacturing landscape, precision,

efficiency, and reliability are paramount. As industries demand

higher standards and more complex applications, the need for

advanced dispensing and potting equipment becomes increasingly

crucial. Enterprising companies are turning to cutting-edge

solutions to meet these demands, leveraging technologies such as

CCD vision systems and dual-component dispensing machines to stay

ahead of the curve.

CCD Vision Dispensing Systems: Revolutionizing accuracy and quality control, CCD vision

dispensing systems integrate advanced imaging technology with

precision dispensing capabilities. By providing real-time visual

feedback and ensuring precise placement of materials, these systems

optimize production processes and minimize waste.

AB Glue Machines:Versatile and robust, AB glue machines are the workhorses of

adhesive application. Whether it's two-part silicone, polyurethane,

or epoxy, these machines excel in metering, mixing, and dispensing

a wide range of materials. With customizable configurations and

automated features, they streamline production workflows and

enhance product consistency.

2K Potting Technology:For applications requiring superior encapsulation and protection,

2K potting technology delivers unmatched performance. By combining

two components precisely at the point of dispensing, this

technology ensures thorough mixing and homogeneity, resulting in

durable and reliable potting solutions.

Automated Dispensing Equipment: Embracing the era of Industry 4.0, automated dispensing equipment

integrates seamlessly into smart manufacturing environments.

Equipped with high-precision dispensing valves and robotic arms,

these systems offer unparalleled efficiency and repeatability,

optimizing production throughput and reducing labor costs.

Dynamic and Static Mixing Systems: Catering to diverse application requirements, dynamic and static

mixing systems provide flexible solutions for a variety of

materials. Whether it's high-viscosity adhesives or low-viscosity

resins, these systems deliver precise mixing ratios and consistent

results, ensuring optimal performance in every application.

Metering, Pouring, and Filling Equipment:From meter-mix dispensing machines to resin casting systems, the

versatility of modern dispensing equipment knows no bounds. Whether

it's sealing, filling, or casting, these machines offer precise

control over material flow and dispensing parameters, empowering

manufacturers to tackle even the most challenging applications with

confidence. In conclusion, the landscape of dispensing and potting

equipment is evolving rapidly, driven by advancements in technology

and the ever-increasing demands of modern manufacturing. By

embracing innovative solutions such as CCD vision systems,

automated dispensing equipment, and dynamic mixing systems,

companies can unlock new levels of efficiency, precision, and

reliability in their production processes. As industries continue

to push the boundaries of innovation, the role of advanced

dispensing equipment will only grow in importance, shaping the

future of manufacturing for years to come.

Introduction :

Introduction :1 Working Area: controlled by PLC module and MCGS touch screen.

2 High precision valve: high speed, glue off clean, no glue

drawing, no dropping.

3 Core technology pumps are designed specially for different

materials from low to high viscosities

4 Mix glue A & B more evenly; no more or no less for agent B.

Working principle :

Compound materials A & B are kept in two tanks separately. There

are two sets of metering pumps inside the machine for metering A

and B resin by setting ratio, draining out material individually

from tank A & B. Liquid A & B mix with each other in the mixer pipe

and dispensed out according to the programmable data.

Tank system technology:

- Stainless panel vacuum pressure tank which can bear negative

pressure of inner tank . 2. Tank with motor stirrer that prevent

the glue from sediment and keep the potting material in constant

temperature.

3 Tank with top/ high /low liquid sensors that ensure alarm warning

when liquid higher or lower the setting level .

4 Tank with vacuum degas (degas time can be set through touch

screen), so the material can be re-feeding through vacuum negative

pressure .

5 Tank with pressure releasing ball valve ; the bottom of tank

reserved back-flow connector and river closure ball valve.

6.Tank with heating panel which can preheat materials to assure

good flowability.

6 Tank with artificial feeding mouth that can be added glue

appropriately by hand .

7 Tank with silica-dryer which can prevent material especially PU

from crystallization .

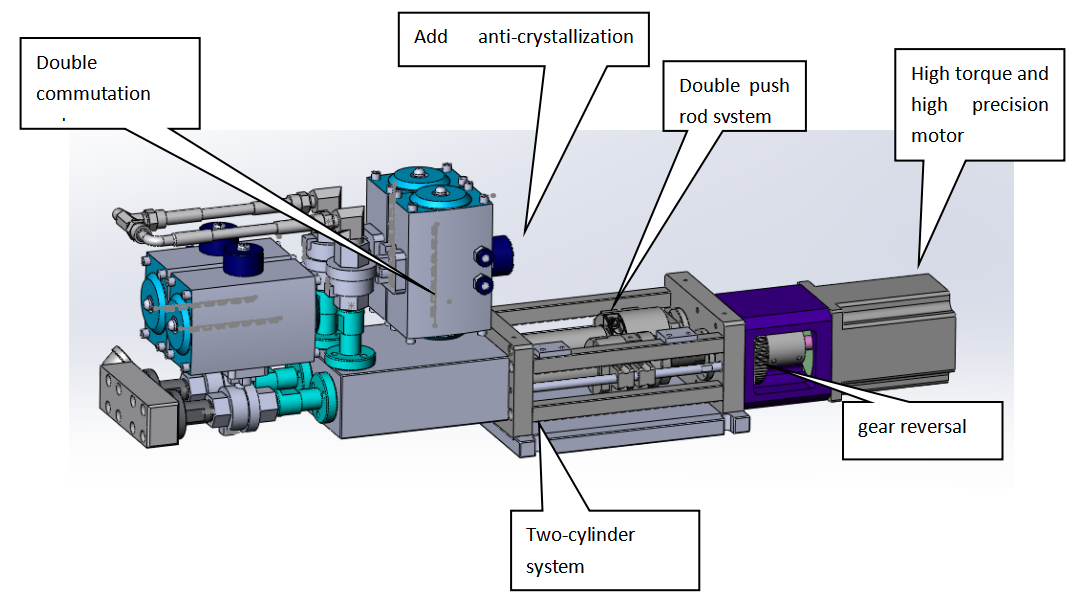

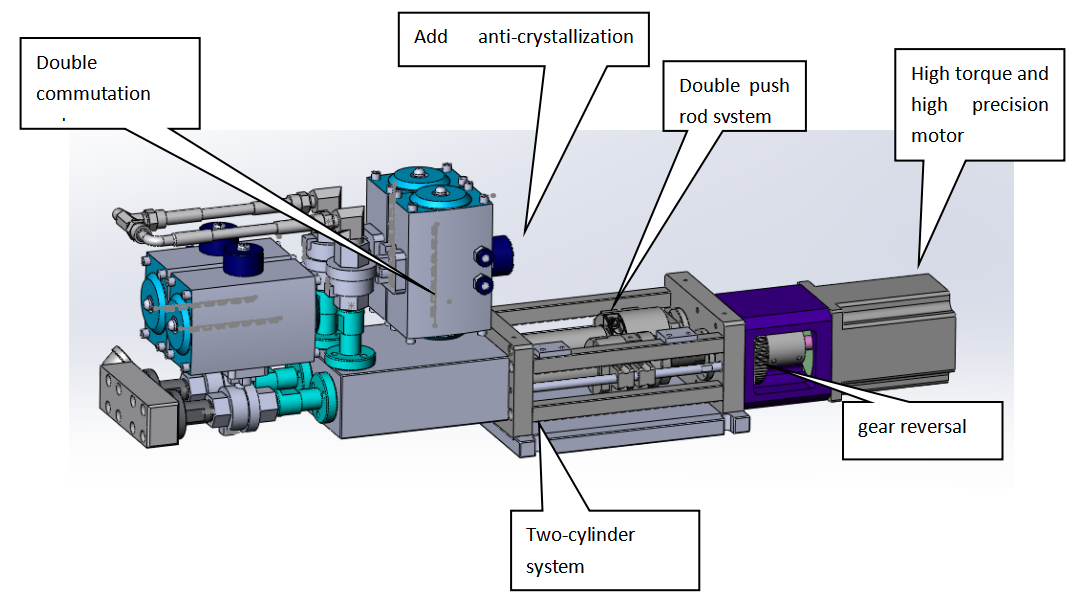

D&H Pump technology

1 Two cylinder plunger pumps work by durable motors.

2 The biggest flow volume :24g/s,Repetition accuracy:0.2g.

3 Also Suitable for high viscosity glue: 50cps~35000cps.

4 Suitable for big flow dispensing or slight flow dispensing.

5 Suitable for frequent start and stop dispensing.

6 Anti-wear, Anti-corrosion, super long life time.

Valve technology

1.Two cylinder plunger pumps work by durable motors.

2.The biggest flow volume :24g/s,Repetition accuracy:0.2g.

3.Also Suitable for high viscosity glue: 50cps~35000cps.

4. Suitable for big flow dispensing or slight flow dispensing.

5. Suitable for frequent start and stop dispensing.

6. Anti-wear, Anti-corrosion, super long life time.

Teach data

| Glue ratio | 1 :1 ---10:1 |

| Ratio acurracy | ±2% |

| Glue-out speed | 0.5g/s --24g/s(Per single pump) |

| Glue-out accuracy | ±2% |

| Program memory | 99pcs |

| Glue viscosity | 50cps~35000cps(Reference data) |

| Opearation Mode | Manual mode /Automatic mode |

| Ratio Control | PLC/ Double plunger pump (Can change different type of metering

pumps) |

| Flow Control | Digital input |

| Parameter display | Pointer / digital display |

| Automatic control system | Touch screen / button switch/ third party signal |

| Mixing Method | Static mixing / Automatic cleaning |

| Storage Tank | Stainless steel A and B(10L,25L ,40L optional) |

| Stainless steel cleaning barrel C(5L) |

| Vacuum degas(-0.1MPa) |

| Liquid level sensor(Low liquid level/high liquid level) |

| A/B Tank stirring |

| AB glue constant temperature heating(available) |

| Glue filter |

| Power | 220V/50Hz/5000W |

| Outer dimension | Glue Potting Machine:995mm×600mm×1500mm |

| Frame Materials | Cold rolled steel/industrial aluminum/stainless steel/sheet metal |

Parameters

| Parameter | Category | Specification |

| Mixing ratio | 1:1-10:1 | Speed | 0-250mm/s(displacement speed) |

| Working area | Inner area:450x400x80mm,Dimension: 900x790x760mm |

| Program memory | 99 pcs | Precision | ±0.1mm (accuracy of displacement)±2%(mixing accuracy) |

| Input air pressure | 0.3MPa-0.8MPa |

| Viscosity range | 50cps~30000cps | Working path | Dot, line , arc , circle |

| Operation mode | JOG/AUTO |

| Control system | PLC | Auto control system | Industrial touch screen program with programming modification,

storage and so on |

| Flow control | Digital input |

| Programming method | Teaching programming | Out-glue control system | AB glue suck-back valve /vacuum suck back skill. |

| Mixing mode | Dynamic |

| Power | 380V/50Hz/1200W | Storage system | Stainless steel tanks A Tank: 40L & B Tank: 25L(10L,25L ,40L

optional) |

| Vacuum degree | -0.1MPa | Vacuum time | 90S(as per different requirement) |

PLC controlling System

1 Dispensing volume is controlled by the speed of pump's motors ;

Glue speed adjustable within the speed range .

2 Machine with detecting function that detect the speed and running

time of pumps to ensure the ratio reliability.

3 Adjustable gluing-out volume make sure glue A/B dispense out at

the same time from glue valve to get better glue mixing effect .

4 Machine with gel resistance calculator , which prevent the

mixture curing inside .

5 You can set single gluing-out and steady gluing-out function to

meet up with your different process requirement .

6 Whole machine system and function is controlled by Panasonic PLC

and MGCS touch screen .

7 Reserved PLC communication interface, which easy connecting with

outside device .

8 Equipped with a safety lock to prevent staff from wrong operation

.

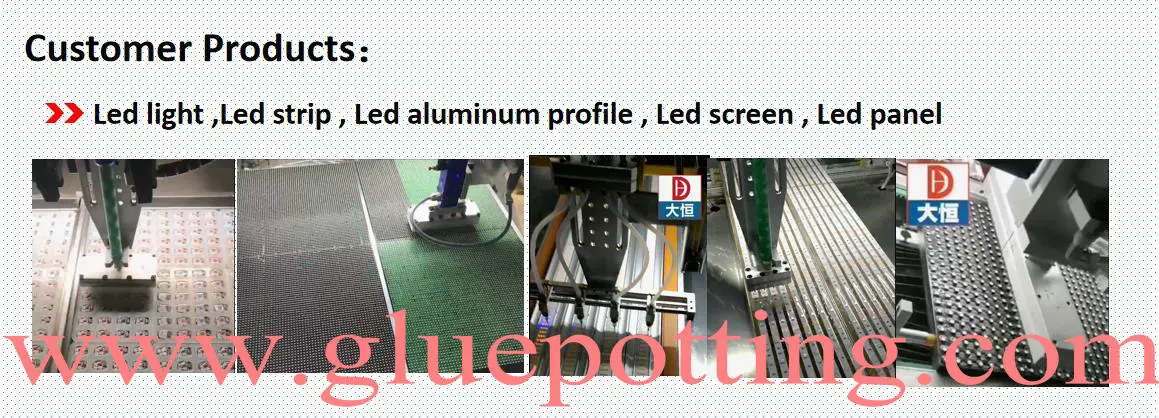

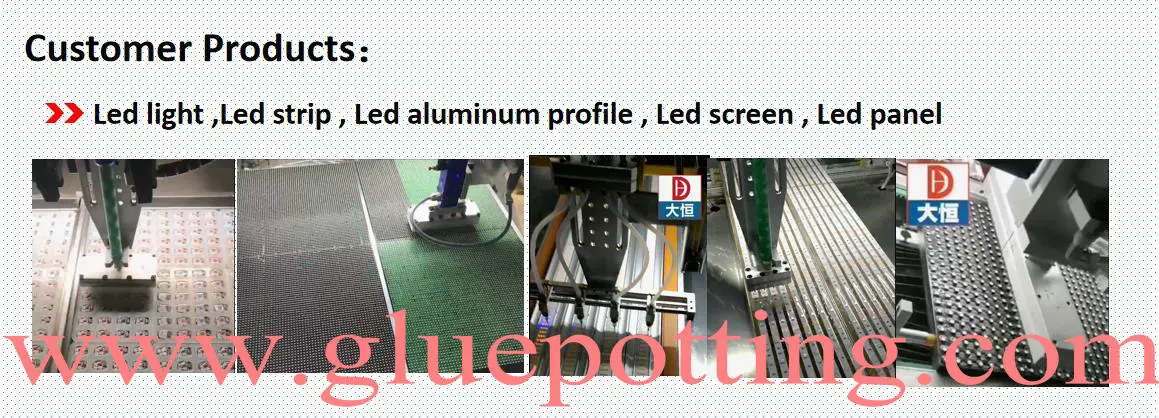

Application:

1.Potting&Encapsulation &Casting: electronics componnets , PCB board, Capacitor, power supply,

transformer, ignition coil, reverse sensor, circuit board, filter

products ,underwater parts, electronic ballast ,aviation parts,

aerospace parts....

2.Dispensing&Dosing : LED strip , led lamp , led bulb , aluminum,led screen , display

module ,medical parts,medical liquid filling ....

3.Bonding&doming : LCD screen ,LOCA bonding,ABS plastic,different types of stickers ,

badge , keychains , souvenirs ,arts , photo frame , and other arts

graphics....

Applicable materials

1K and 2-component polyurethanes, epoxies, acrylics, silicones,

temperature, humidity and UV curing materials. Two component

potting materials , 2-part compound materials, AB part compound

materials , 2K silicones ,2K epoxies resin, Bi-component PU,

Ployerster, Polyurethane, UV materials and so on .Service Term

1K and 2-component polyurethanes, epoxies, acrylics, silicones,

temperature, humidity and UV curing materials. Two component

potting materials , 2-part compound materials, AB part compound

materials , 2K silicones ,2K epoxies resin, Bi-component PU,

Ployerster, Polyurethane, UV materials and so on .Service Term

1.Staff training

Seller is responsible to provide machine's training including

installation, debugging, maintenance to assured customer can

totally use the operation skills and well acknowledge maintenance

of machine .2.Maintenance Service

2.1Seller provide one year warranty period and support free

maintenance service during warranty . Software upgrade service is

provided for a long life time.2.2 In case parts of the machine become broken within the warranty

because of non-artificial factors, we send you part replacement

free, buyer pay for the shipment. Double-liquid valve should be

bought at its cost price.2.3If the parts of the machine become broken past warranty , the

parts replacement should be shouldered by buyer.Workshop Cornner of factory

Shipping&delivery

Sucessful cases: