Customized full Automatic Glue Dispenser Machine Three -part

adhesive gluing machine

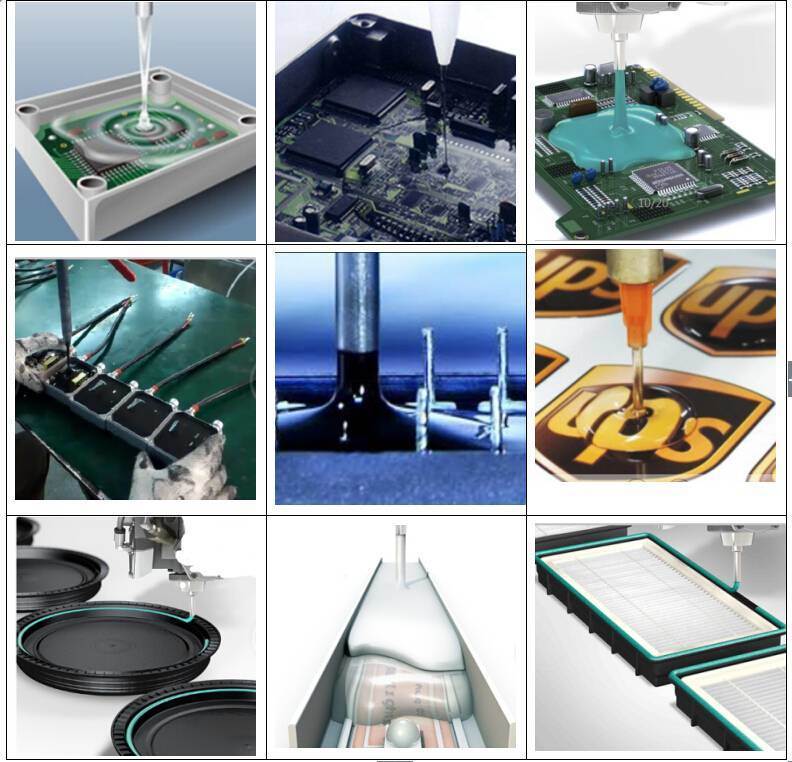

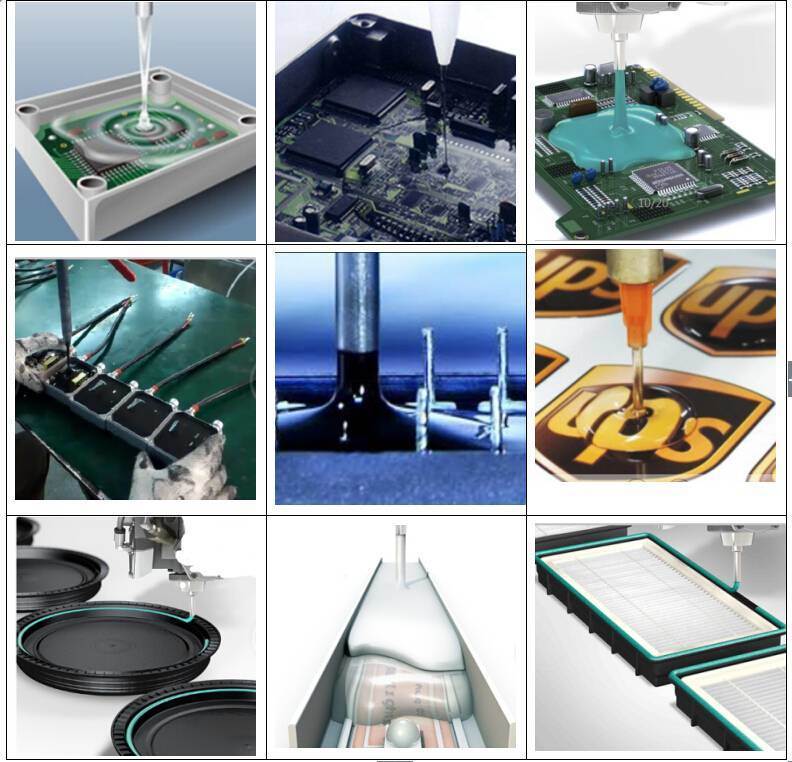

Electronics are increasingly present in our lives, these

technologies all use a wide array of components -sensors,

actuators,central processing units (CPUs), printed circuit boards

(PCB), electronics components , Capacitor, power supply,

transformer,ignition coil, reverse sensor, circuit board, filter

products ,underwater parts, electronic ballast ,aviation parts,

aerospace parts....etc. - that need to be protected against

environmental factors such as dust and moisture, as well as fluids

and heat andfire exposure.

Our 2 component application equipment is the the good machine for

potting and encapsulating vary parts and products, which apply

different production processes required metering , mixing , dosing

, dispensing and potting with high accuracy and high efficiency.

We Daheng Automation specialize in different types of potting and

dispensing system. No matter what your resin application

requirements look like: we can do most of them in our fully

equipped lab. We can handle 1- and 2-component polyurethanes,

epoxies, acrylics, silicones, temperature, humidity and UV curing

materials. They can be from low- to high-viscosity, filled or

unfilled and even high abrasive for thermal conductivity.

Potting is the process of embedding products & assemblies in a

liquid resin (potting compounds) to protect them against rough

environment conditions. Potting can be performed in atmosphere

pressure or even under vacuum, if high voltage insulation and high

temperature differences are needed.

We offer automatic ,se-mi automatic fluid dispensing potting

machine and the related production line and vacuuming systems . Introduction :

Introduction :1. Working Mode

: controlled by PLC module and MCGS touch screen.2.High precision valve: high speed, glue off clean, no glue

drawing, no dropping. 3. Core metering pump specially design for

different material from low to high viscosities. 4. Mix glue A & B

more evenly; no more or no less for agent B.Working principle :Compound materials A & B are kept in two tanks separately. There

are two sets of metering pumps inside the machine for metering A

and B resin by setting ratio, draining out material individually

from tank A & B. Liquid A & B mix with each other in the mixer pipe

and dispensed out according to the programmable data.Tank system technology:1. Stainless panel vacuum pressure tank which can bear negative

pressure of inner tank . 2. Tank with motor stirrer that prevent

the glue from sediment and keep the potting material in constant

temperature. 3 Tank with top/ high /low liquid sensors that ensure

alarm warning when liquid higher or lower the setting level . 4

Tank with vacuum degas (degas time can be set through touch

screen), so the material can be re-feeding through vacuum negative

pressure . 5 Tank with pressure releasing ball valve ; the bottom

of tank reserved back-flow connector and river closure ball valve.6 Tank with heater which can preheat materials to assure good

flowability . 7 Tank with artificial feeding mouth that can be

added glue appropriately by hand . 8 Tank with silica-dryer which

can prevent material especially PU from crystallization .

Application:

Industry: Capacitor, power supply, transformer, ignition coil,

reverse sensor, circuit board, electronic ballast, other electronic

products and LED products where glue potting demanded.

D&H Pump technology1. Two cylinder plunger pumps work by durable motors. 2.The biggest

flow volume :24g/s,Repetition accuracy:0.2g. 3.Also Suitable for

high viscosity glue: 50cps~35000cps. 4. Suitable for big flow

dispensing or slight flow dispensing. 5. Suitable for frequent

start and stop dispensing. 6. Anti-wear, Anti-corrosion, super long

life time.

D&H Pump technology1. Two cylinder plunger pumps work by durable motors. 2.The biggest

flow volume :24g/s,Repetition accuracy:0.2g. 3.Also Suitable for

high viscosity glue: 50cps~35000cps. 4. Suitable for big flow

dispensing or slight flow dispensing. 5. Suitable for frequent

start and stop dispensing. 6. Anti-wear, Anti-corrosion, super long

life time.Glue:

Epoxy, silica gel, AB glue, PU and other glue which need matching

Optional Function:

1, evacuation

2, heating

3, Geared pump & plunger piston pump are available; Customers can

choose to needs.

4, Control-card will be chosen to be added in to program to needs.

| Model & Type | PGB-700 Full Auto Gluing Machine Dispenser |

| Certificate | CE, SGS |

| Dimension | 1500x1200x1500mm |

| N.W. | 260kg |

| XYZ Working Area | 700x700x80mm |

| Flow Speed | 0-66g/5s, or customized |

| Moving Speed | 0-300mm per second |

| Glue & Ratio | 1:1 to 20:1, Epoxy, Silicone, PU, UV |

| Repeatability | +/-0.02g |

| Accuracy | +/- 1% |

| Power | AC220V or AC 380V |

| Total Power Consume | 3kw - 5kw |

| Additional Function | Heating, Vacuum, Self-refilling, Self-cleaning |

| Application | LED module, display, LED lights, power supply, driver, motor,

sensor, and transformer and so on^

|