Automatic glue dispensing machine PGB1560D

Features and Benefits:

1, A system of metering, mixing and potting.

2, Accurate metering and even mixing helps to avoid possible waste

of glue.

3, Shot size and positioning keep consistent, fast.

4, Good universality makes PGB1560D suitable for applications of

LED, electric and others glue potting needed.

5, Easy to program and operate.

6, Tally function, non-standard mode, primer mode, level alert,

filter mode, liquid display device, preventing backflow device and

other functional device.

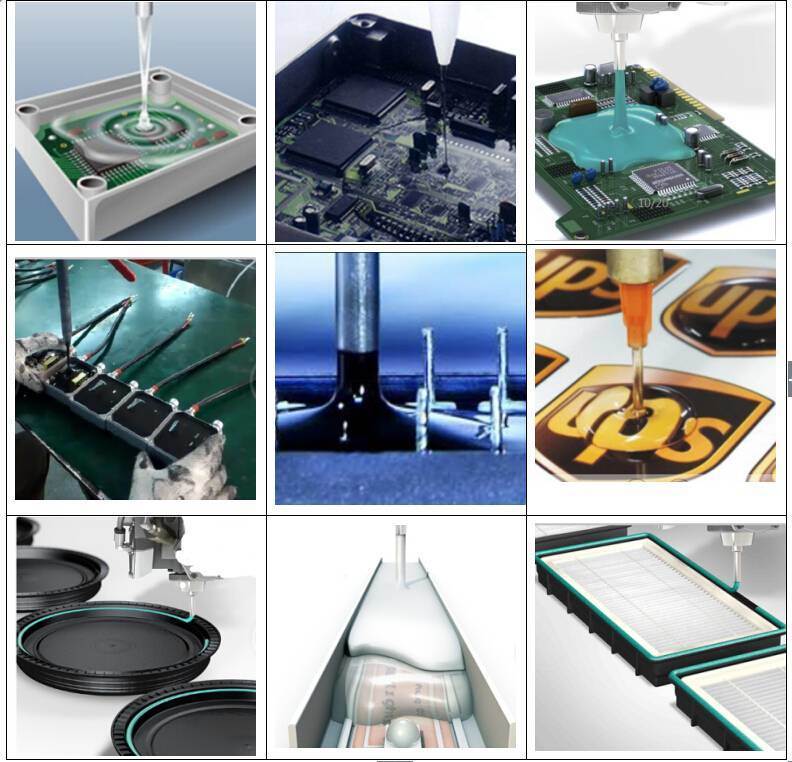

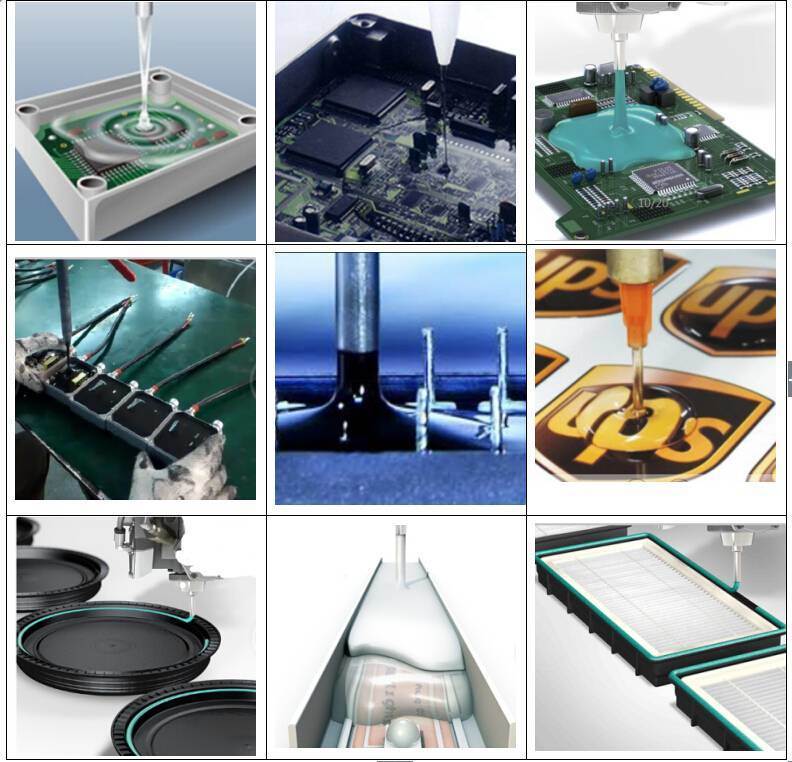

Application:

Industry: Capacitor, power supply, transformer, ignition coil,

reverse sensor, circuit board, electronic ballast, other electronic

products and LED products where glue potting demanded.

Glue:

Epoxy, silica gel, AB glue, PU and other glue which need matching

Optional Function:

1, evacuation

2, heating

3, Geared pump & plunger piston pump are available; Customers can

choose to needs.

4, Control-card will be chosen to be added in to program to needs.

| Model & Type | PGB-1560D Full Auto Gluing Machine Dispenser |

| Certificate | CE, SGS |

| Dimension | 1500x1200x1500mm |

| N.W. | 600kg |

| XYZ Working Area | 1560x550x80mm |

| Flow Speed | 0-150g/5s, or customized |

| Moving Speed | 0-300mm per second |

| Glue & Ratio | 1:1 to 20:1, Epoxy, Silicone, PU, UV |

| Repeatability | +/-0.02g |

| Accuracy | +/- 1% |

| Power | AC220V or AC 380V |

| Total Power Consume | 3kw - 5kw |

| Additional Function | Heating, Vacuum, Self-refilling, Self-cleaning |

| Application | LED module, display, LED lights, power supply, driver, motor,

sensor, and transformer and so on^

|

Advantages:

1,Accurated metering and even mixing helps to avoid the waste of material.

2,Dispensing volume and positioning keep machine work consistent and fast.

3,Good universality

4,Easy to program and operate.

5,Tally function, non-standard mode, primer mode, level alert, filter

mode, liquid display device, preventing back-flow device and other

functional device.

Features&Functions:

Strong versatility / Multiple configuration / High production capacity / High precision- Auto feeding : take use of vacuum pressure to feed materials into A&B tank

separately.

- Tank Stirring : A and B tank configure with stirring motors and blades to prevent

material sediment in the tank bottom .

- Heating : Tank , pipe , pumps are optional with heaters to assure the whole

system can be heating from room temperature to 90°C adjustable.

- Vacuum : A &B tank vacuum for degas the bubble inside material .

- Dynamic mixing : Configuring dynamic motor and mixer to mix A and B fluids evenly.

Suitable MaterialTwo component potting materials , 2-part compound materials, AB part compound materials , 2K silicones ,2K epoxies resin, Bi-component PU, Ployerster, Polyurethane, UV materials and so on .Machine description and working principleCompound materials A & B are kept in two tanks separately. There are two sets of

metering pumps inside the machine for metering A and B resin by setting ratio, draining out material individually from tank A & B. Liquid A & B mix with each other in

the mixer pipe and dispensed out according to the programmable

data.

Suitable MaterialTwo component potting materials , 2-part compound materials, AB part compound materials , 2K silicones ,2K epoxies resin, Bi-component PU, Ployerster, Polyurethane, UV materials and so on .Machine description and working principleCompound materials A & B are kept in two tanks separately. There are two sets of

metering pumps inside the machine for metering A and B resin by setting ratio, draining out material individually from tank A & B. Liquid A & B mix with each other in

the mixer pipe and dispensed out according to the programmable

data.Company Profile

Guangzhou Daheng Automation Equipment CO., Ltd is specialized in

the R&D and sale of glue metering, mixing and dispensing

machinery.We believe in "the creation improves future". Core technology is

the only true creation. The e core of all the liquid controlling

device is its metering and mixing system. Daheng, always taking its

continuous efforts in the new technology, new products and new

working process, created its unique tech "double- cylinder pump",

which is a liquid control system of high precision, changeable,

continuous and long span time, and can be applied with glues of

different viscosity. The core technology makes us the first pioneer

in the gluing machine industry which passed CE certificate, SGS. We

have over 20 patents, many original products and many "first" in

the industry.Including the standard machines we already have, we also accept

customized services. We,headed in Guangzhou, and branched in

Zhongshan, Shenzhen, Shanghai, and exported into Russia, Turkey,

Netherland, Singapore, Indonesia and so on.

We provide the on-going train-up for customers, 24 hours x 7 days

service, and keep ourselves being improved on and on.The current and great development of Daheng depends on your support

and trust. We will keep ourselves making long effort in the

industry and products. We will keep improved in the cylinder pump

and precision valve, and keep the leading among our competitors.