Company Introduction

Guangzhou Zhengqi Technology Co., Ltd. recognized as a national

high-tech enterprise, specializes in automation system integration

and services, offering cutting-edge products and solutions to

global markets.

Guangzhou Daheng Automation Equipment Co., Ltd. operates as a

wholly-owned subsidiary of Guangzhou Zhengqi Technology Co., Ltd.,

forming a synergistic partnership that drives innovation and

excellence within the group.

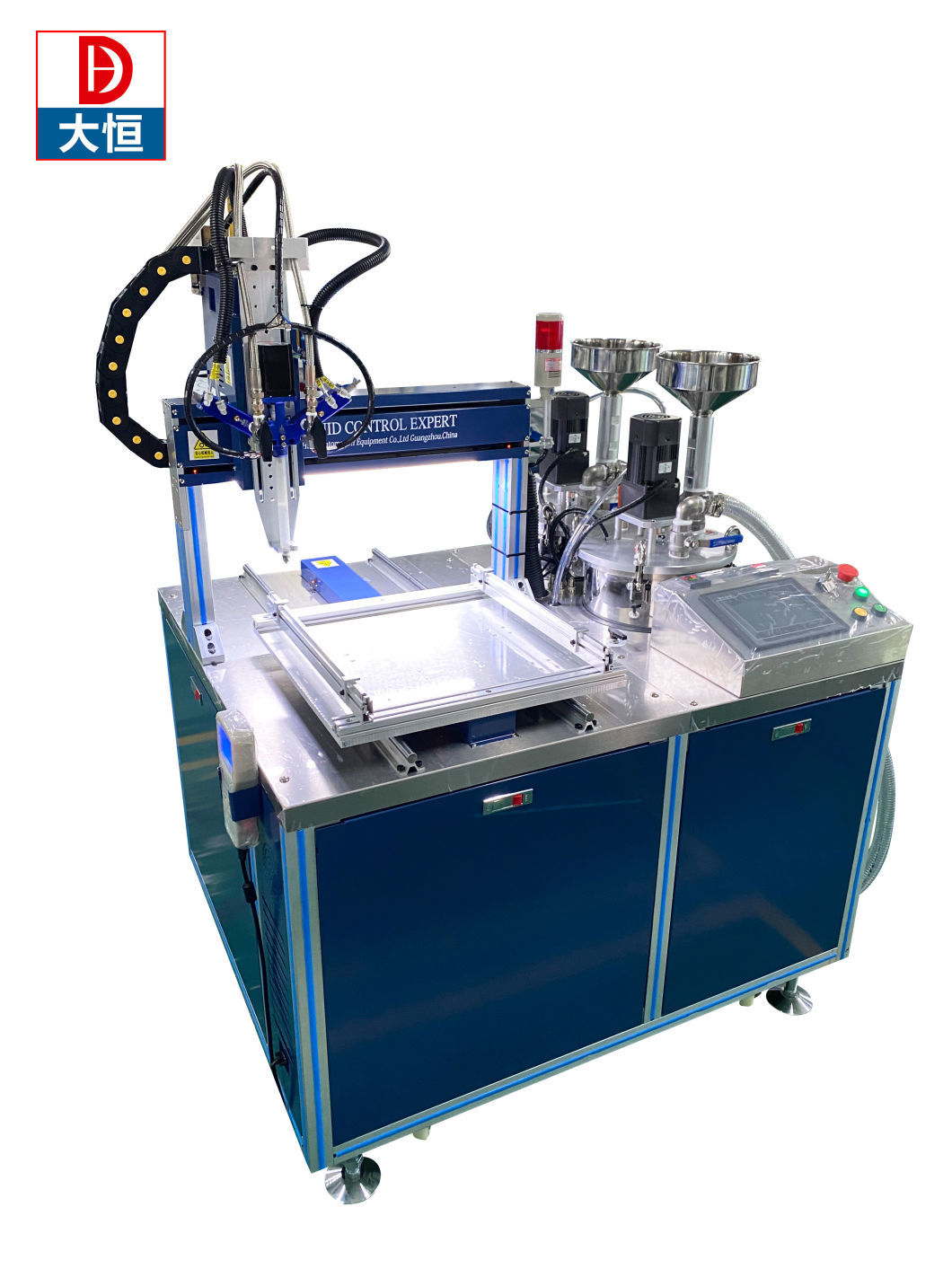

As the production and development arm of the group, Daheng

Automation excels in the design, manufacturing, and maintenance of

adhesive control process equipment and production lines. It serves

diverse industries, including new energy, automotive, electronics,

lighting, and intelligent manufacturing, catering to both domestic

and international markets. Daheng Automation has established itself

as a pioneer in liquid control technologies. In 2006, the company

introduced the patented “double-cylinder plunger pump,” a

groundbreaking innovation in adhesive dispensing. This technology

revolutionized high-performance metering systems, enhancing

precision and efficiency, particularly for applications involving

high-viscosity, high-crystallization, and high-output-speed

materials. In 2015, Daheng Automation launched the world’s first

"Intelligent poting machine" dispenser. This revolutionary product

integrated advanced computation, communication, remote control, and

self-management functionalities, marking a significant milestone in

adhesive control technology. Until 2024, with over 60 patents,

Daheng Automation continues to lead the industry in technological

advancements.

While Daheng Automation drives innovation in production and

equipment development as an international brand. Zhengqi Technology

focuses on overseas sales, international trade, and strategic

market expansion. Together, the companies operate under a unified

legal and financial framework, ensuring operational efficiency and

cohesion.

The headquarter is located in Guangzhou, China, Daheng

Automation has established branches in key cities such as Shenzhen,

Beijing, Shanghai, Xiamen, and Chongqing. The company collaborates

with clients in over 60 countries, including Germany, the USA,

South Korea, Russia, and India, reflecting its strong global

footprint.

Guided by the philosophy “Success Comes from Details, Innovation

Improves the Future,” Daheng Automation and Zhengqi Technology

prioritize customer satisfaction through 24/7 support, regular

training programs, software upgrades, and continuous product

improvement. Their unwavering commitment to quality and innovation

solidifies their position as global leaders in adhesive control

solutions.

#mixing #metering #Pouring #potting #dispensing #Dosing

#encapsulating #spraying #sealing #filling #casting equipment